With the rapid popularization of electric vehicles (EVs) in recent years, DC charging piles (fast-charging piles), as the critical infrastructure for fast energy replenishment, have attracted widespread attention for their technical composition and working principles. Among their core components, DC energy meters serve as an indispensable metering device, playing a pivotal role in the charging process. To understand why DC charging piles must be equipped with dedicated DC energy meters instead of conventional AC energy meters, an in-depth analysis is required from multiple perspectives, including charging principles, metering accuracy, and commercial operation.

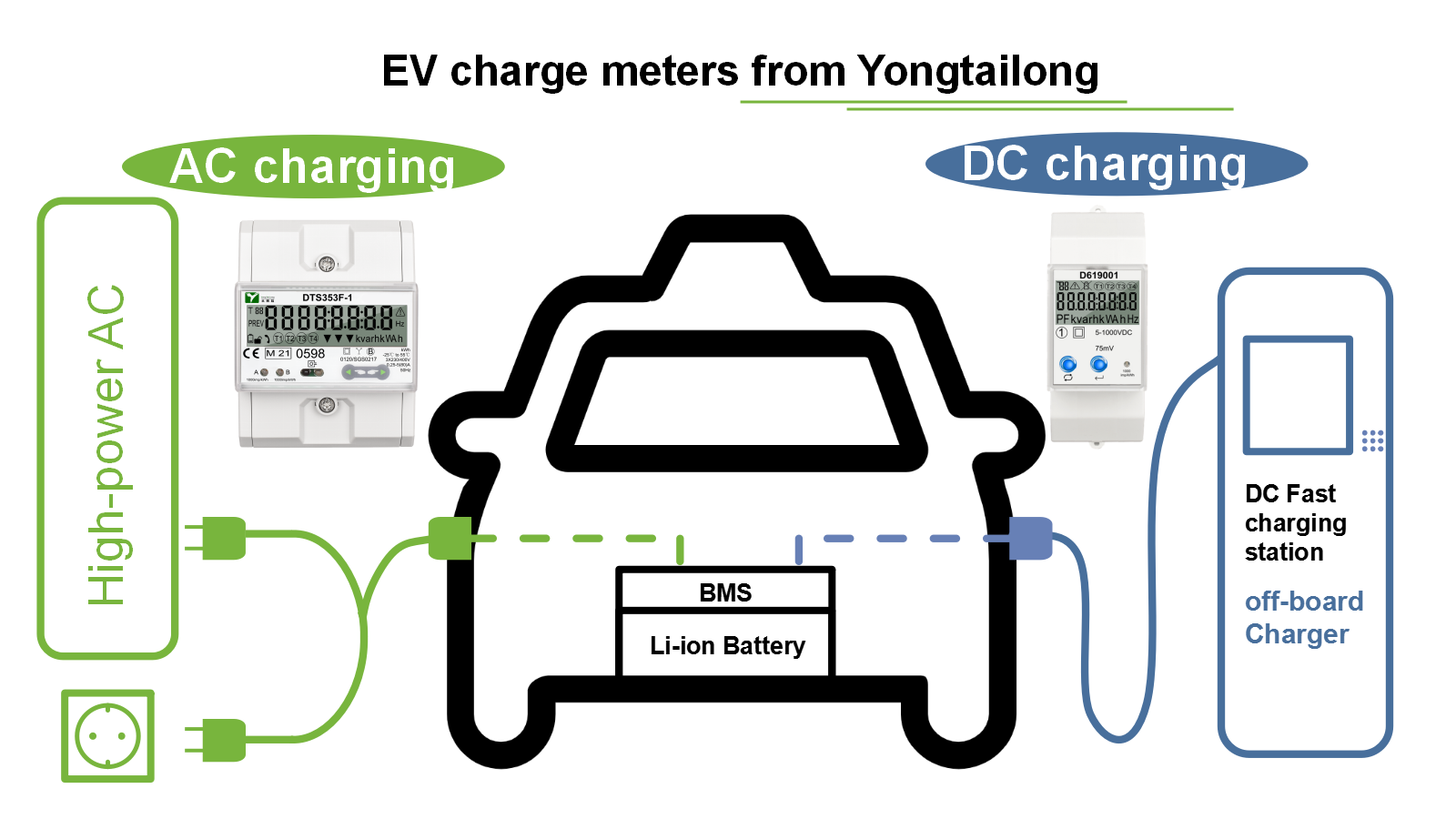

1. Charging Principles of AC-DC Conversion Determine the Metering Point

The fundamental function of a DC charging pile is to convert and transmit electrical energy in different forms. The power supplied by the grid to the charging pile is alternating current (AC), while the EV power battery accepts and stores direct current (DC). Therefore, the internal structure of the charging pile must first utilize AC/DC conversion units such as rectifiers and power modules to convert the input AC into DC that matches the voltage and current characteristics of the battery. Only after this conversion process is the electrical energy delivered to the EV’s charging interface. Using an AC energy meter for metering after this conversion would be as erroneous as using a raw water meter to measure the volume of purified drinking water after filtration.

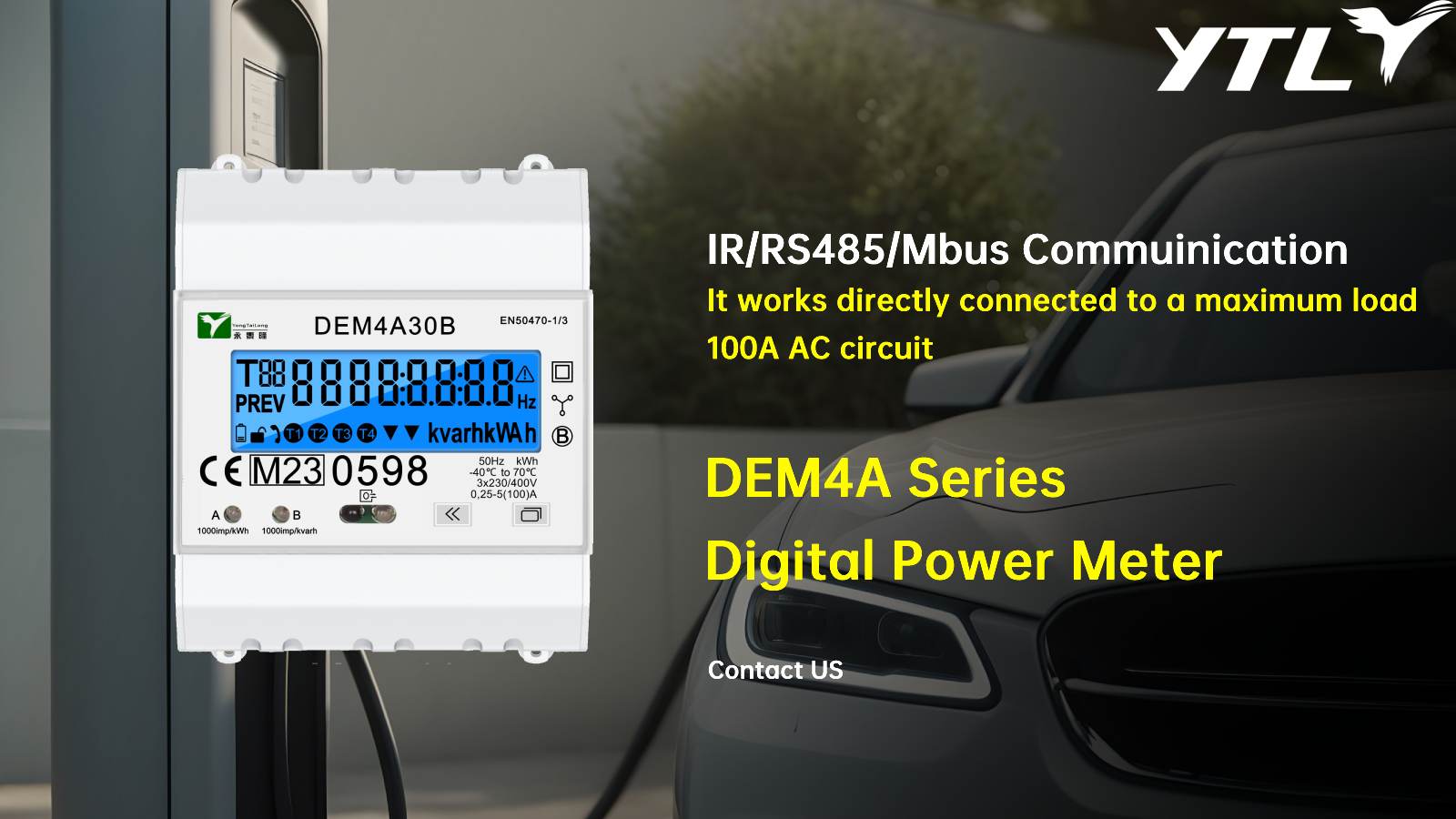

DC energy meters are connected in series in the DC output circuit after the rectifier, directly measuring the converted DC energy that is about to be charged into the battery. This principle of "metering where energy is consumed" ensures consistency between the metered object and the actual energy consumed, laying the physical foundation for fair metering.

2. An Imperative Requirement for Ensuring Fair Trade Settlement and High Precision

As commercial operation facilities, the accuracy of the energy metering data from charging piles directly impacts the economic interests of both operators and consumers. DC charging typically features high power, short charging duration, and high single-charging costs, thus imposing extremely stringent requirements on metering precision.

DC energy meters are specifically designed and calibrated for measuring DC parameters. They can directly measure DC voltage and current without additional conversion, thereby calculating power and cumulative energy consumption, and minimizing measurement errors introduced by intermediate links.

In addition, the EV charging process is dynamically regulated by the Battery Management System (BMS), resulting in wide fluctuations in voltage and current (e.g., current can range from several amperes to hundreds of amperes). Professional DC energy meters are engineered to accommodate this characteristic, relying on high-linearity current sensors (such as closed-loop Hall sensors or precision shunts) and high-speed, high-precision ADCs (Analog-to-Digital Converters) to achieve Excellent metering accuracy across a broad dynamic range. Maintaining accuracy throughout the entire charging process—from trickle charging to peak power charging—is the core technical guarantee for building consumer trust and avoiding settlement disputes. This is also a universal requirement specified in global metrological regulations, with clear standards outlined in international norms such as IEC 62053-41 for static DC energy meters.

3. The Data Foundation for System Monitoring and Intelligent Management

The operational management of modern DC charging piles has evolved beyond basic charging functions, moving toward intelligence and networking. In this process, DC energy meters provide far more than just a final energy consumption reading. As precision measurement units, they can real-time monitor key electrical parameters on the DC side, including output voltage, output current, instantaneous power, and power quality (such as ripple).

These real-time data form the "sensory system" for the intelligent management of charging piles. The operation management platform can leverage this data to assess the stability of the charging process, conduct necessary fault diagnosis and early warning (e.g., triggering protective shutdowns in case of detected overvoltage or overcurrent). More importantly, these data serve as the critical basis for realizing dynamic power distribution among multiple charging guns in a station, optimizing charging curves to extend battery lifespan, conducting refined energy efficiency analysis, and preparing for metering in future Vehicle-to-Grid (V2G) bidirectional energy flow systems. Without the accurate DC-side data provided by DC energy meters, charging piles would merely function as "black-box" actuators, leading to significant compromises in their safety, economic efficiency, and intelligence level.

Conclusion

The necessity of using DC energy meters in DC charging piles is jointly determined by their core AC-to-DC working principle, the stringent requirements for fair trade settlement, and the in-depth needs of intelligent operation management. DC energy meters act not only as the "standard scale" for fair charging but also as the "monitor" for ensuring the safe and stable operation of the system, and even more importantly, as the "data cornerstone" supporting the future intelligent charging ecosystem. With the advancement of fast-charging technology toward ultra-fast charging (>350kW) and even megawatt-level charging, the precise metering and high reliability of DC energy meters under higher power levels and more complex operating conditions will become increasingly vital and irreplaceable.

English

English 简体中文

简体中文

.png?imageView2/2/w/500/h/500/format/png/q/100)