In the fields of modern electrical distribution and industrial automation, guide rail meters demonstrate extraordinary technical charm with their unique design concepts. This compact electric meter, installed with standardized 35mm rails, perfectly embodies the engineering philosophy of "small yet strong". Its innovative installation method not only greatly simplifies the assembly process, but also provides unprecedented flexibility and convenience for system integration. The revolutionary breakthrough of this design concept has made rail meters an indispensable core component in intelligent power distribution and energy management, redefining the application value of power measurement equipment.

Revolutionary breakthrough in standardized installation

The most prominent feature of the guide rail watch is its innovative installation method. By adopting the internationally recognized 35mm standard guide rail installation specifications, the traditional fixed mode of electric meters has been completely changed. Installation personnel do not need complex drilling and positioning, they only need to align the instrument buckle with the guide rail and gently push it to complete mechanical fixation, greatly reducing installation time and labor costs. This standardized installation ensures that products from different manufacturers have the same size, providing users with more freedom of choice and convenient replacement. The compact size allows multiple instruments to be installed side by side, maximizing the saving of valuable space in the distribution box and leaving room for layout of other electrical components. This installation method not only improves work efficiency, but also reduces the difficulty of system integration and maintenance costs in the later stage.

High integration of tiny spaces

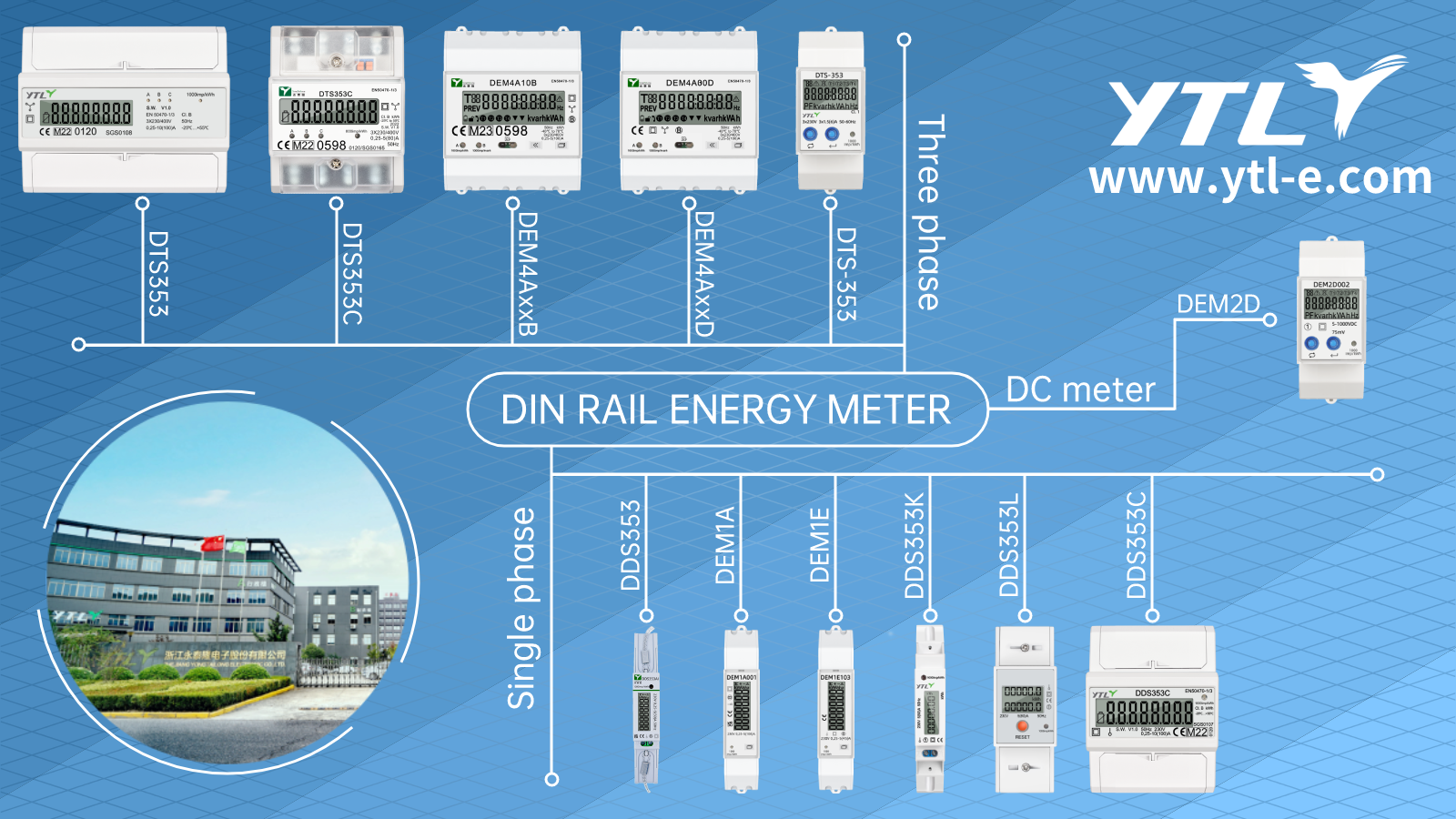

Despite its compact size, the rail watch contains astonishing technological density and functional integrity. Modern rail gauges integrate complete functional components such as high-precision measurement chips, signal processing units, communication modules, and display interfaces within a limited space. Its measurement accuracy can reach level 0.5 or even higher, and it can accurately measure dozens of power parameters such as voltage, current, power, and electrical energy. Advanced signal processing algorithms can analyze real-time power quality indicators such as harmonic content and voltage fluctuations, providing in-depth diagnostic information for power systems. At the same time, it is equipped with rich communication interfaces, supporting various methods such as RS485, Ethernet, wireless communication, etc., to ensure seamless integration of measurement data into various monitoring systems. This highly integrated design demonstrates the outstanding ability of modern electronic technology to miniaturize complex functions.

Widely applicable adaptability

The significant advantage of rail watches lies in their wide applicability and system compatibility. This flexible design makes it suitable for various scenarios, from simple energy metering to complex energy management systems, from industrial automation to intelligent building distribution, and rail meters can find their place in use. In the manufacturing industry, real-time monitoring of equipment energy consumption can be installed on the production line; In commercial buildings, it can be used for sub item measurement and energy auditing; In the field of infrastructure, provide reliable measurement data for power monitoring. Standardized communication protocol support enables the rail gauge to easily connect to various automation systems such as PLC, DCS, SCADA, etc., achieving seamless integration with different brands of equipment. This excellent compatibility greatly simplifies the complexity of system design and equipment selection.

Future prospects for intelligent development

With the development of the Internet of Things and Industry 4.0 technology, rail watches are evolving towards a more intelligent direction. The new generation of intelligent guideway meter not only has the basic measurement function, but also integrates the edge computing ability to complete data analysis and processing tasks locally. The integration of cloud computing technology enables rail tables to be directly connected to cloud platforms, enabling remote monitoring and management of data. The introduction of artificial intelligence algorithms enables it to have pattern recognition and predictive analysis capabilities, which can automatically identify abnormal electricity consumption patterns and provide optimization suggestions. The in-depth application of modular design concept enables users to select different functional modules according to their actual needs, achieving true on-demand configuration. These technological innovations continuously enhance the value connotation of guide rail meters, transforming them from simple measuring devices to important nodes in intelligent energy management systems.

The guide rail watch, with its compact size and powerful functions, perfectly embodies the design wisdom of "seeing the big with the small" in modern engineering technology. The standardized installation method, highly integrated functions, wide adaptability to applications, and continuous intelligent development together constitute the unique charm of guide rail watches. This innovative design not only solves the problems of inconvenient installation and maintenance of traditional electricity meters, but also provides more flexible and efficient solutions for intelligent power distribution and energy management. With the advancement of technology, guide rail meters will undoubtedly demonstrate their value in more application fields and make important contributions to building more intelligent, efficient, and reliable energy management systems.

English

English 简体中文

简体中文

.png?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)