When the global number of new energy vehicles exceeds 43.78 million and the charging pile market is growing at an annual rate of 50%, meter manufacturers are quietly standing on the "new C-position" of the energy revolution. From the millisecond response of DC fast charging stations to the power dispatch of virtual power plants, from precise billing of household charging stations to energy management of heavy-duty truck supercharging stations, meter manufacturers are leveraging the underlying logic of the billion dollar charging station market with "metering" as the pivot.

1、 Technological Battle: Evolution from "Precision" to "Omnipotent"

Charging station metering is not a simple replica of traditional electricity meters. In the 800V high-voltage fast charging scenario, meter manufacturers need to overcome three major technical difficulties:

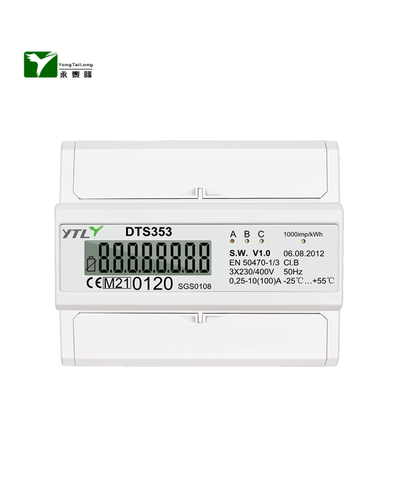

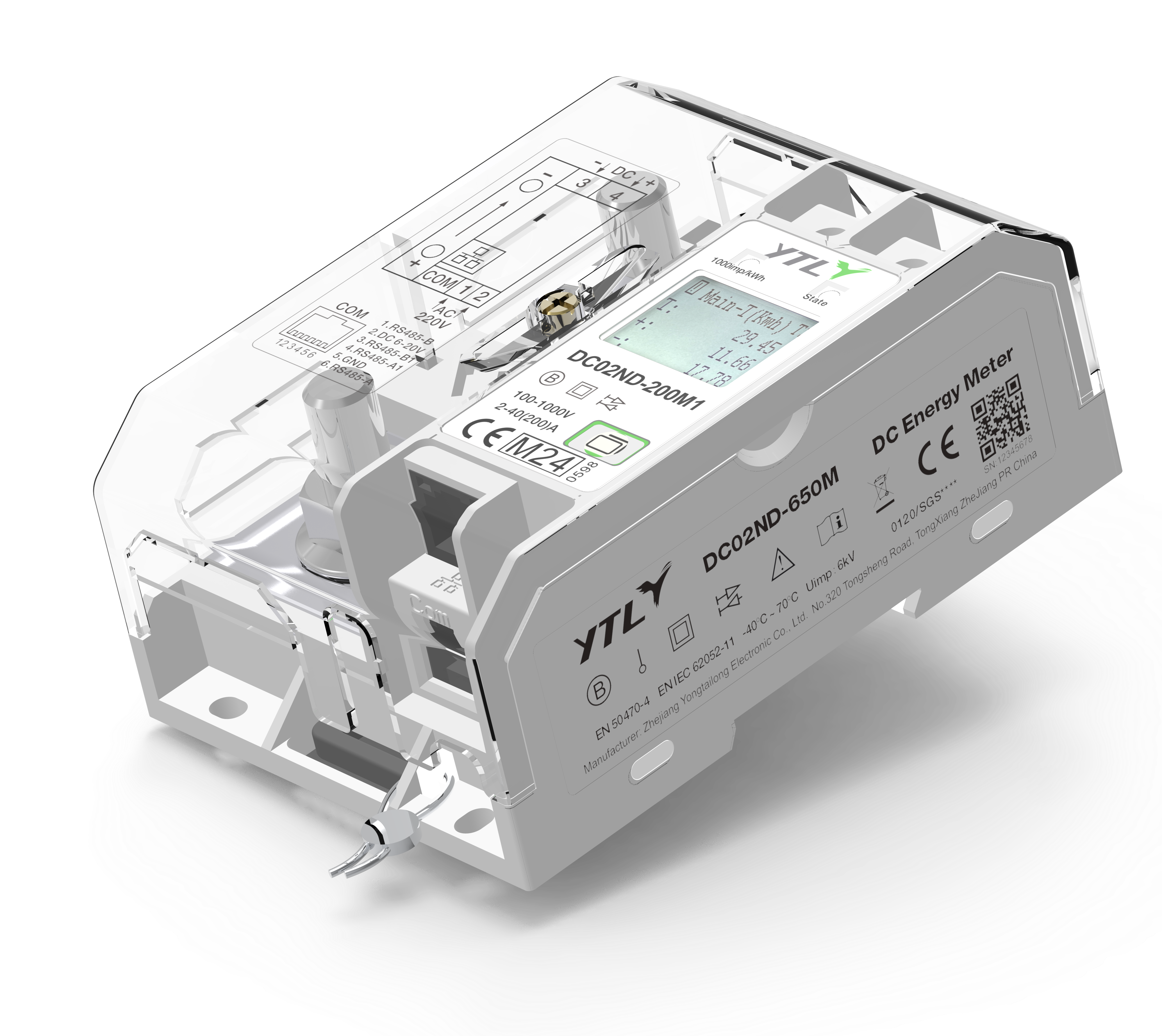

Ultra wide range metering: Yongtailong's DC02ND series integrated DC energy meter is designed with a shunt and metering chip to achieve full range coverage of 0-1000V voltage and 650A current, with an error rate of less than 0.5%, ensuring accurate billing for heavy truck overcharging piles with a range of 800 kilometers.

Dynamic power allocation: Flexible charging stack technology requires the electricity meter to respond in real-time to the dynamic adjustment of the power pool. The commonly used 240-960kW DC charging pile in the market adopts a dual gun power dynamic allocation algorithm, and the electricity meter needs to complete the power allocation calculation within milliseconds to avoid power disputes during multi vehicle charging.

Extreme environmental adaptability: Charging stations in ports, mines, and other scenarios need to withstand temperature differences of -40 ℃ to 70 ℃. Yongtai Long's DC02ND series DC electric meters break the stereotype of "charging station=delicate equipment" through wide temperature chips, dual 85LCD, and three proof paint technology.

2、 Scene Battle: Ecological Penetration from Home to Power Grid

The battlefield of electricity meter manufacturers has extended to the entire lifecycle of charging stations:

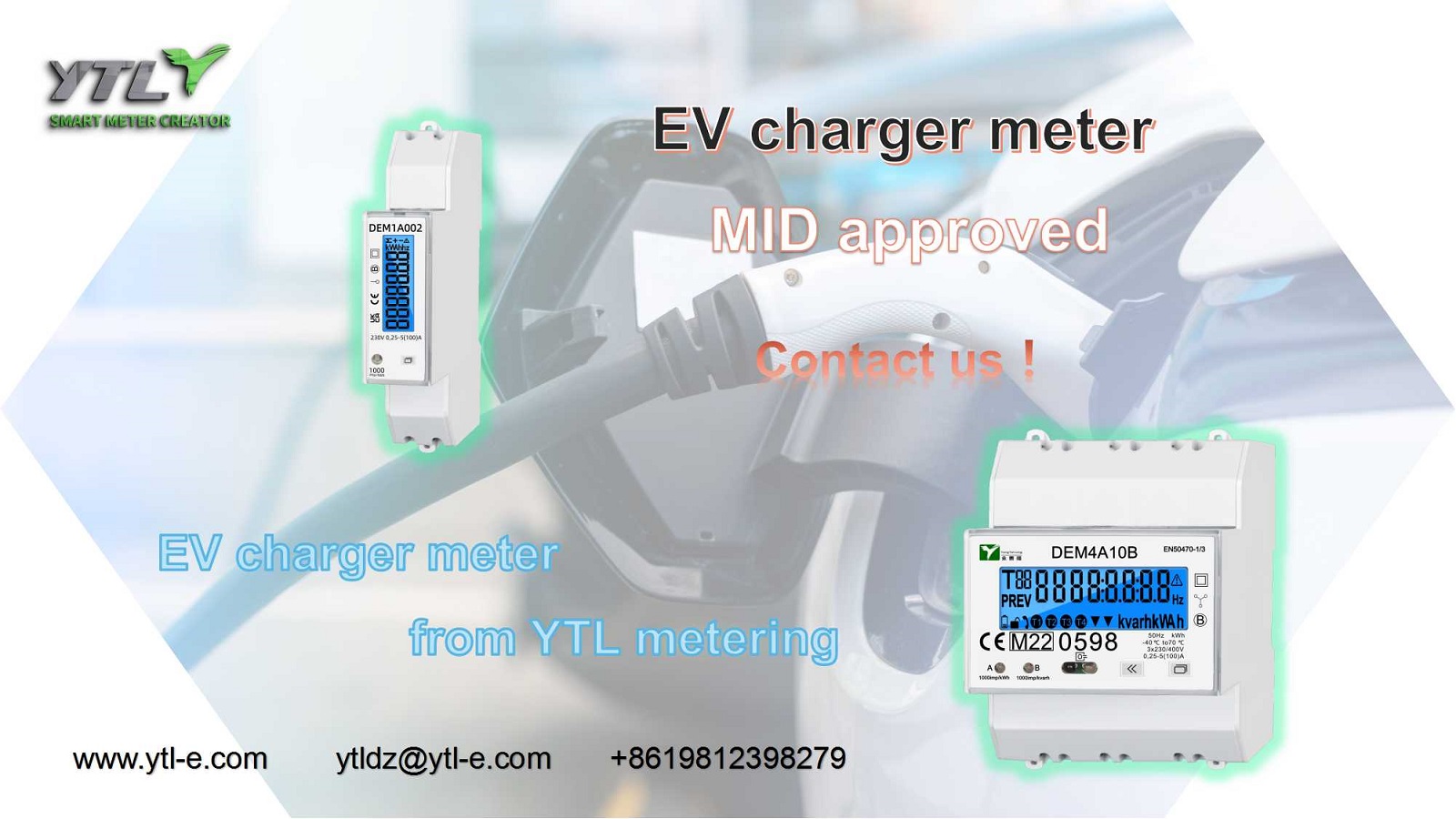

Family scenario: The 7kW household pile needs to be compatible with single-phase/three-phase electricity meters. The Yongtai Long DEM1A/DEM4A series single-phase/three-phase electricity meters are installed through 35mm rails and are compatible with home distribution boxes. They support remote meter reading through an APP and automatic switching between peak and valley electricity prices, allowing private car owners to reduce their nighttime charging costs by 40%.

Commercial scenario: Small power DC piles in shopping mall parking lots need to balance cost and efficiency. Yongtai Long DC02ND DC meter supports Modbus RTU/DL/T 645 dual protocol, with a daily average service of 20 trains per single station and a failure rate of less than 0.3%.

Grid level scenario: Virtual power plants incorporate charging stations into the power dispatch network. Electric meter manufacturers need to embed V2G (vehicle to grid) bidirectional metering function into charging piles. A certain brand of electric meter has achieved "15 minute response to grid peak shaving instructions", transforming electric vehicles into "mobile energy storage stations" and increasing the annual income of car owners by over 3000 yuan.

3、 Standard Battle: From 'Made in China' to 'Global Rules'

As Chinese charging pile companies accelerate their overseas expansion, meter manufacturers are becoming the dominant players in technical standards

International certification barrier: The EU CE certification requires electricity meters to pass EMC electromagnetic compatibility testing at a precision level of 0.5. A certain electricity meter manufacturer has achieved a 60% reduction in radiated interference in the 50Hz-1GHz frequency band by optimizing PCB layout and shielding design, and has passed the German T Ü V certification in one go.

Localized adaptation: There is a 220V/380V hybrid power grid in the Southeast Asian market. Electric meter manufacturers develop dual voltage automatic switching technology

Carbon measurement revolution: EU CBAM carbon tariffs force carbon accounting for the entire lifecycle of charging stations. A certain electricity meter manufacturer has established a blockchain traceability system, which enables the full process of carbon emission data from earth permanent magnet material mining to meter scrapping and recycling to be uploaded to the chain, helping customers avoid a 15% carbon tariff cost.

4、 Ecological Breakthrough Battle: From "Hardware Supplier" to "Energy Steward"

Top electricity meter manufacturers have broken away from the logic of "selling devices" and built an energy data ecosystem:

Value added data service: A certain brand of electricity meter uses AI to analyze users' charging habits and generate a "fleet energy consumption profile" for logistics enterprises, helping them optimize charging strategies and save electricity costs.

Insurance risk control cooperation: Real time monitoring of insulation resistance and grounding status of charging piles by electric meters to ensure charging safety

Carbon trading interface: The electricity meter data is connected to the carbon trading market, and through carbon emission reduction trading of charging piles, profits are earned to achieve a commercial closed loop.

When charging stations become a new type of infrastructure, the value of electricity meter manufacturers has already surpassed the measurement itself. They are the "translators" of the power grid and electric vehicles, the "neurons" of virtual power plants, and even the "data miners" of the carbon neutral era. Those manufacturers whose energy efficiency breaks through the three technical bottlenecks of high-precision measurement, multi protocol compatibility and edge computing will surely write their own names in this energy revolution. After all, in every kilowatt hour of electricity flow, there is a vast sea of stars belonging to the meter manufacturer.

English

English 简体中文

简体中文