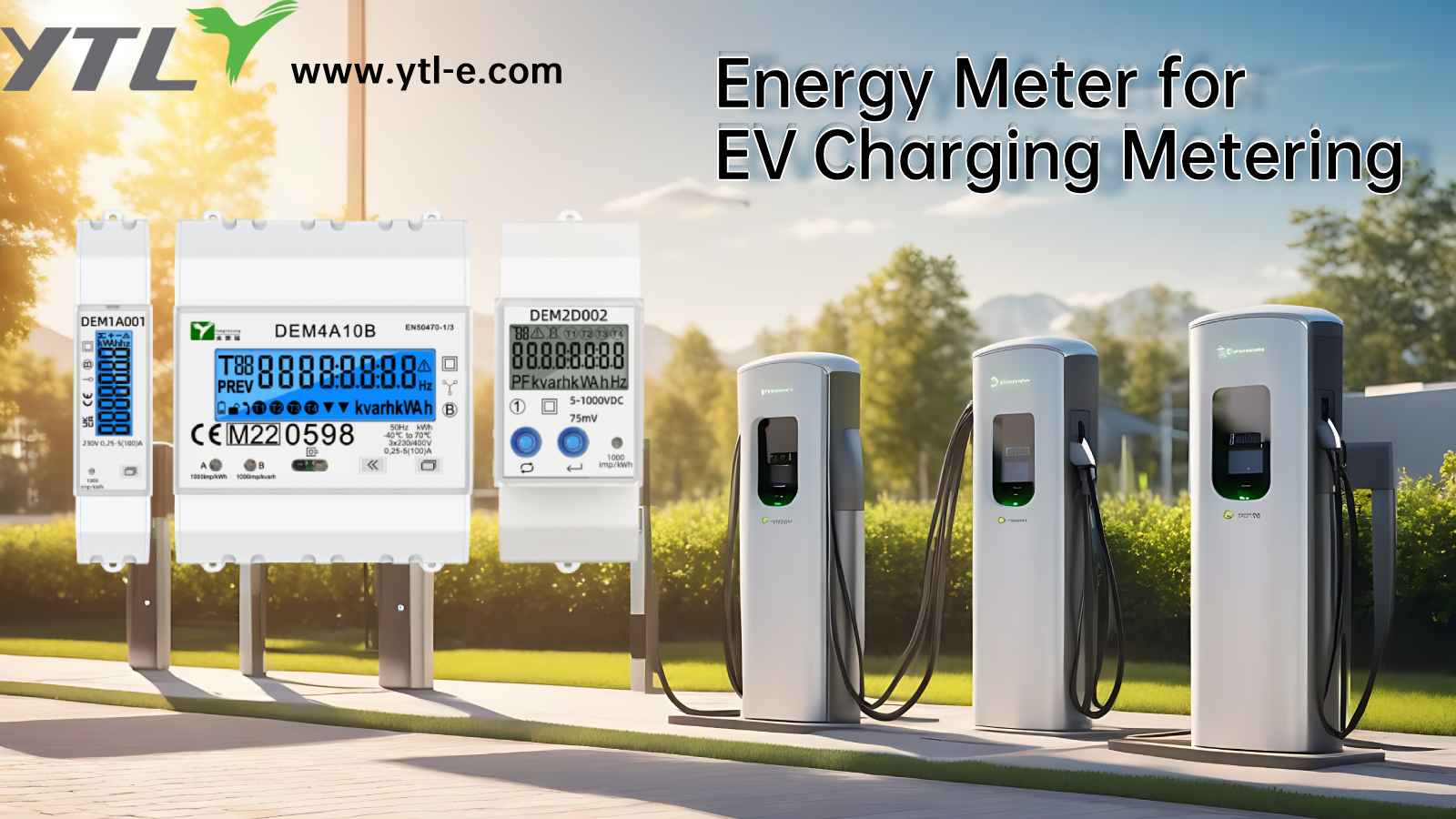

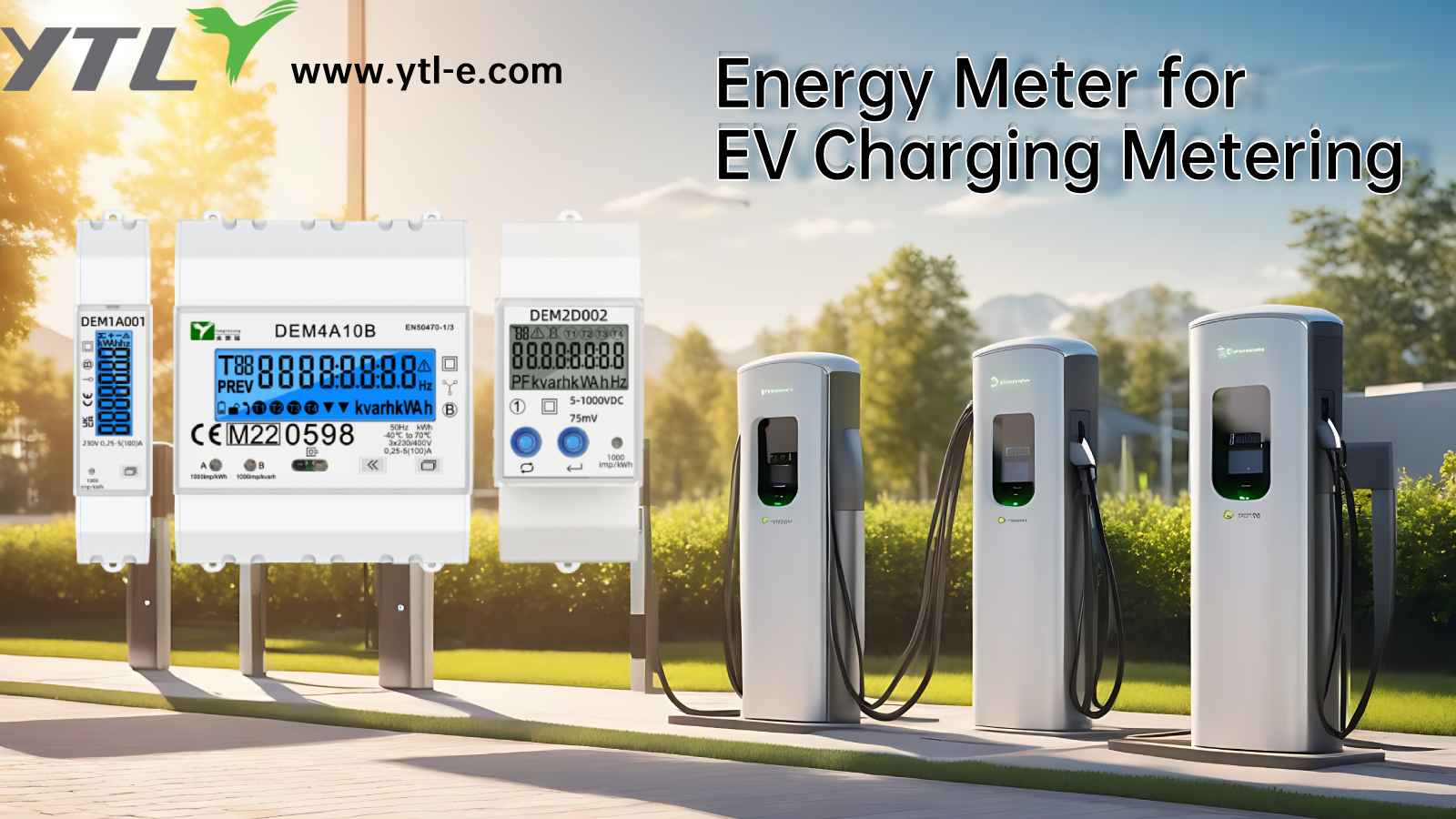

With the rapid popularization of electric vehicles, DC charging piles, as the key infrastructure for fast energy replenishment, have attracted much attention for their technical composition and working principles. Among them, DC electric meters, as an indispensable core metering component inside charging piles, play a crucial role. To understand why DC charging piles must be equipped with dedicated DC electric meters instead of common AC electric meters, we need to conduct an in-depth analysis from multiple dimensions such as charging principles, metering accuracy, and commercial operation.

1. Charging Principle of AC-DC Conversion Determines the Metering Point

The essential function of a DC charging pile is to complete the conversion and transmission of electrical energy forms. The power grid delivers alternating current (AC) to the charging pile, while the power battery of an electric vehicle receives and stores direct current (DC). Therefore, the charging pile first needs to use power conversion modules such as rectifiers to convert the input AC into DC that matches the voltage and current characteristics of the battery. Only after this conversion process is completed is the electrical energy transmitted to the charging interface of the vehicle. If an AC electric meter were used for metering after this point, it would be equivalent to charging customers based on the reading of a raw water meter even after the tap water has been filtered into drinking water—a completely erroneous practice. DC electric meters are connected in series in the DC output circuit after the rectifier, directly measuring the converted DC power that is about to be charged into the battery. This principle of "metering where the energy is used" ensures the consistency between the metered object and the consumed object, laying the physical foundation for fair metering.

2. An Inevitable Requirement to Ensure Fairness and High Precision in Trade Settlement

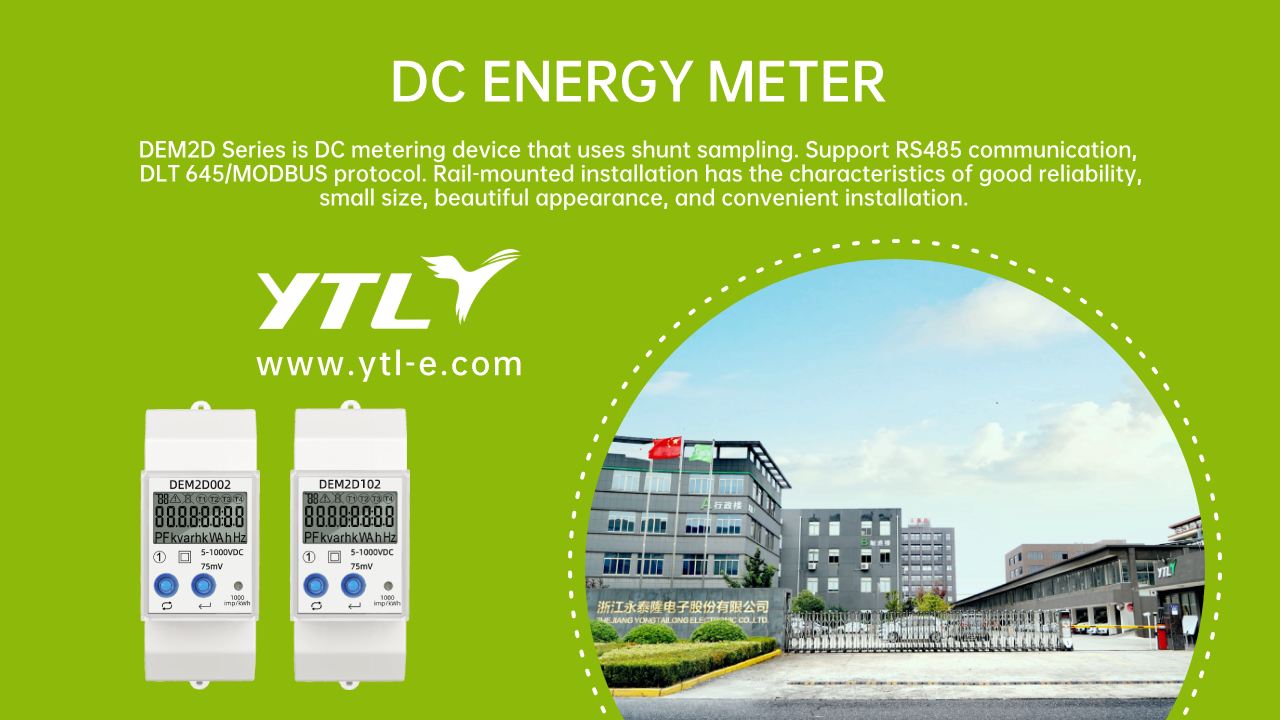

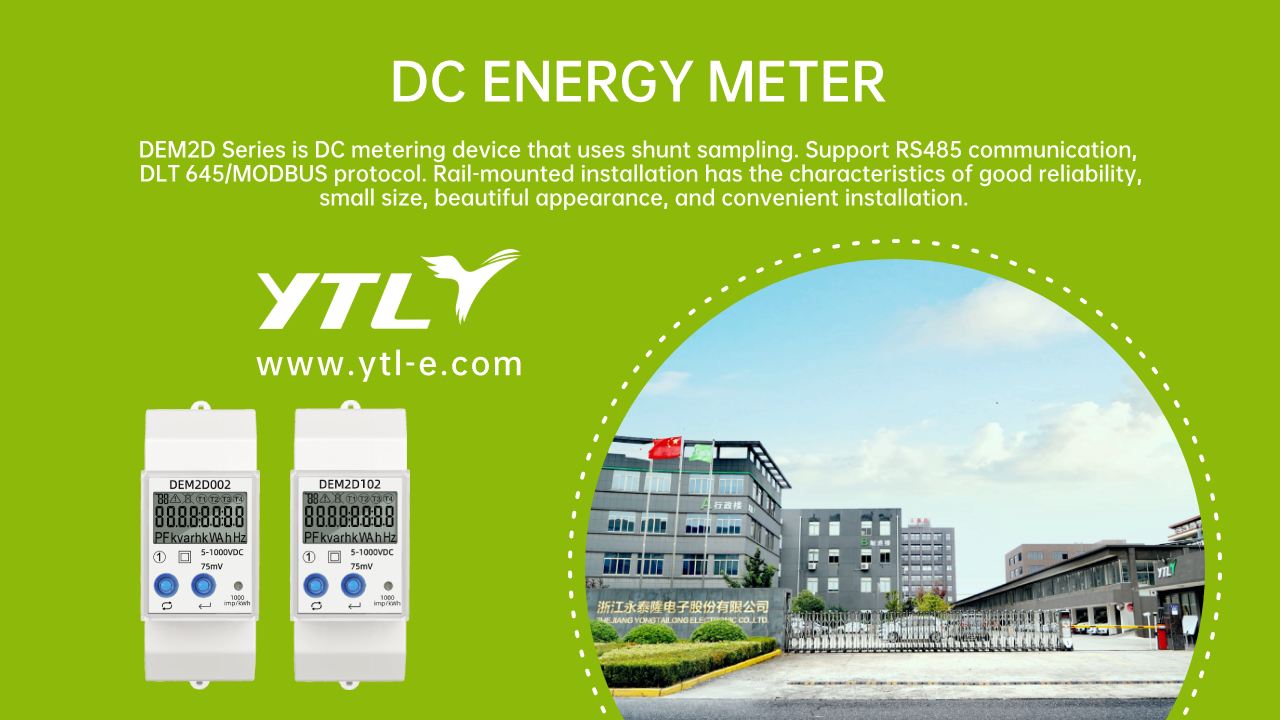

As commercial operation facilities, the accuracy of the energy metering data of charging piles is directly related to the economic interests of both operators and consumers. DC charging typically features high power, short duration, and high single-charge costs, thus imposing extremely stringent requirements on metering precision. DC electric meters are instruments specifically designed and calibrated for measuring DC parameters; they can directly measure DC voltage and DC current without conversion, thereby calculating power and accumulated energy and minimizing measurement errors introduced by intermediate links. In addition, the charging process of an electric vehicle is not constant but follows a complex curve dynamically regulated by the battery management system, with voltage and current varying over a wide range. Professional DC electric meters possess high-precision characteristics across a wide measurement range, maintaining excellent linearity and accurate metering results throughout the entire charging process, from the initial small current to the peak high power. This precise metering capability serves as the core technical guarantee for establishing consumer trust and avoiding settlement disputes, and it is also a basic requirement of relevant metrological regulations for trade settlement equipment.

3. The Data Foundation for Realizing System Monitoring and Intelligent Management

The operation and management of modern DC charging piles have long gone beyond the single function of charging and are moving towards intelligence and networking. In this process, DC electric meters provide far more than just a final electricity reading. As a precision measurement unit, they can real-time monitor key electrical parameters on the DC side, such as output voltage, output current, and instantaneous power. These real-time data constitute the "sensory system" for the intelligent management of charging piles. The operation and management platform can use these data to judge the stability of the charging process and conduct necessary fault diagnosis and early warning—for example, taking protective shutdown measures promptly when abnormal output is detected. Meanwhile, these data also serve as an important basis for optimizing operation strategies, analyzing equipment utilization rates, and implementing energy efficiency management. Without the accurate DC-side data provided by DC electric meters, charging piles would be nothing more than "black-box" actuators, and their safety and intelligence levels would be greatly compromised.

In summary, the necessity of using DC electric meters for charging piles is jointly determined by their core AC-to-DC working principle, the high demand for fairness in trade settlement, and the in-depth needs of intelligent operation management. DC electric meters are not only the "standard scales" for realizing fair charging but also the "monitors" for ensuring the safe and stable operation of the system. With the development of fast-charging technology towards higher power levels, the role of DC electric meters in precise metering and data support will become increasingly irreplaceable.

# Why DC Electric Meters Are a Must for Charging Piles With the rapid popularization of electric vehicles, DC charging piles, as the key infrastructure for fast energy replenishment, have attracted much attention for their technical composition and working principles. Among them, DC electric meters, as an indispensable core metering component inside charging piles, play a crucial role. To understand why DC charging piles must be equipped with dedicated DC electric meters instead of common AC electric meters, we need to conduct an in-depth analysis from multiple dimensions such as charging principles, metering accuracy, and commercial operation. ## 1. Charging Principle of AC-DC Conversion Determines the Metering Point The essential function of a DC charging pile is to complete the conversion and transmission of electrical energy forms. The power grid delivers alternating current (AC) to the charging pile, while the power battery of an electric vehicle receives and stores direct current (DC). Therefore, the charging pile first needs to use power conversion modules such as rectifiers to convert the input AC into DC that matches the voltage and current characteristics of the battery. Only after this conversion process is completed is the electrical energy transmitted to the charging interface of the vehicle. If an AC electric meter were used for metering after this point, it would be equivalent to charging customers based on the reading of a raw water meter even after the tap water has been filtered into drinking water—a completely erroneous practice. DC electric meters are connected in series in the DC output circuit after the rectifier, directly measuring the converted DC power that is about to be charged into the battery. This principle of "metering where the energy is used" ensures the consistency between the metered object and the consumed object, laying the physical foundation for fair metering. ## 2. An Inevitable Requirement to Ensure Fairness and High Precision in Trade Settlement As commercial operation facilities, the accuracy of the energy metering data of charging piles is directly related to the economic interests of both operators and consumers. DC charging typically features high power, short duration, and high single-charge costs, thus imposing extremely stringent requirements on metering precision. DC electric meters are instruments specifically designed and calibrated for measuring DC parameters; they can directly measure DC voltage and DC current without conversion, thereby calculating power and accumulated energy and minimizing measurement errors introduced by intermediate links. In addition, the charging process of an electric vehicle is not constant but follows a complex curve dynamically regulated by the battery management system, with voltage and current varying over a wide range. Professional DC electric meters possess high-precision characteristics across a wide measurement range, maintaining excellent linearity and accurate metering results throughout the entire charging process, from the initial small current to the peak high power. This precise metering capability serves as the core technical guarantee for establishing consumer trust and avoiding settlement disputes, and it is also a basic requirement of relevant metrological regulations for trade settlement equipment. ## 3. The Data Foundation for Realizing System Monitoring and Intelligent Management The operation and management of modern DC charging piles have long gone beyond the single function of charging and are moving towards intelligence and networking. In this process, DC electric meters provide far more than just a final electricity reading. As a precision measurement unit, they can real-time monitor key electrical parameters on the DC side, such as output voltage, output current, and instantaneous power. These real-time data constitute the "sensory system" for the intelligent management of charging piles. The operation and management platform can use these data to judge the stability of the charging process and conduct necessary fault diagnosis and early warning—for example, taking protective shutdown measures promptly when abnormal output is detected. Meanwhile, these data also serve as an important basis for optimizing operation strategies, analyzing equipment utilization rates, and implementing energy efficiency management. Without the accurate DC-side data provided by DC electric meters, charging piles would be nothing more than "black-box" actuators, and their safety and intelligence levels would be greatly compromised. In summary, the necessity of using DC electric meters for charging piles is jointly determined by their core AC-to-DC working principle, the high demand for fairness in trade settlement, and the in-depth needs of intelligent operation management. DC electric meters are not only the "standard scales" for realizing fair charging but also the "monitors" for ensuring the safe and stable operation of the system. With the development of fast-charging technology towards higher power levels, the role of DC electric meters in precise metering and data support will become increasingly irreplaceable.