As electric vehicles (EVs) shift from being "policy-driven" to "market-driven", the billing accuracy of charging piles has become one of the core factors for users when choosing a service provider. However, traditional charging piles often suffer from disputes such as users being "overcharged" or operators experiencing "reduced revenue" due to issues like large current measurement errors and severe harmonic interference. As the "metering core" of charging piles, DC meters (DC energy meters), with their high accuracy, anti-interference capabilities, and bidirectional metering features, are reshaping the industry rules for charging billing. This article will use practical cases and technical analysis to reveal how DC meters fundamentally solve billing errors and inject "precision genes" into the EV ecosystem.

I. The "Three Major Pain Points" of Traditional Charging Pile Billing: Where Do Errors Come From?

Pain Point 1: "Ambiguous" Current Measurement, Billing Relies on "Estimated Values"

Traditional charging piles mostly adopt a combined solution of shunts and ordinary energy meters: shunts convert large currents into small voltage signals, and energy meters calculate electricity consumption through integration. However, shunts have a temperature drift issue (for every 10℃ increase in temperature, the resistance value changes by 0.4%), leading to an expansion of current measurement errors as charging time increases. Additionally, ordinary energy meters have insufficient ability to capture dynamic currents (such as transient impacts during charging start/stop), and can only estimate electricity consumption based on "average values", resulting in an error rate often exceeding ±3%.

Pain Point 2: "Amplified" Harmonic Interference, "False Increase" in Electricity Consumption Becomes Commonplace

EV charging modules generate a large number of harmonics (especially 3rd and 5th harmonics). If traditional energy meters are not equipped with harmonic compensation functions, they will mistakenly count harmonic power as active power, leading to a "false increase" in electricity consumption.

Pain Point 3: "Missing" Bidirectional Metering, V2G Services Struggle to Launch

With the promotion of Vehicle-to-Grid (V2G) technology, charging piles need to support bidirectional metering for "charging-discharging". However, most traditional energy meters are designed for unidirectional use and cannot distinguish current direction, making it impossible to accurately calculate users' discharge revenue—a major obstacle to the commercialization of V2G.

II. How Do DC Meters Solve Billing Problems? Revealing Three Core Technologies

Technology 1: High-Precision Current Measurement: From "Estimation" to "Actual Measurement"

DC meters use closed-loop Hall sensors or fluxgate sensors instead of shunts to achieve non-contact current measurement, completely eliminating the temperature drift issue.

Technology 2: Harmonic Compensation and Effective Value Metering: Rejecting "False Increases" in Electricity Consumption

DC meters have a built-in harmonic analysis module that can real-time separate fundamental wave power from harmonic power, and only integrate and meter the fundamental active power.

Technology 3: Bidirectional Metering and Dynamic Tariffs: Supporting V2G and Time-of-Use Electricity Prices

DC meters use bidirectional current sensors and dual-channel metering chips to simultaneously record charging and discharging electricity consumption. They also support dynamic tariff models such as time-of-use pricing and demand response. Moreover, DC meters can accurately calculate the revenue difference between charging and discharging, providing data support for V2G services.

III. The "Golden Partnership" of DC Meters and CT Meters: Building a "Precision Metering Chain" for Charging Piles

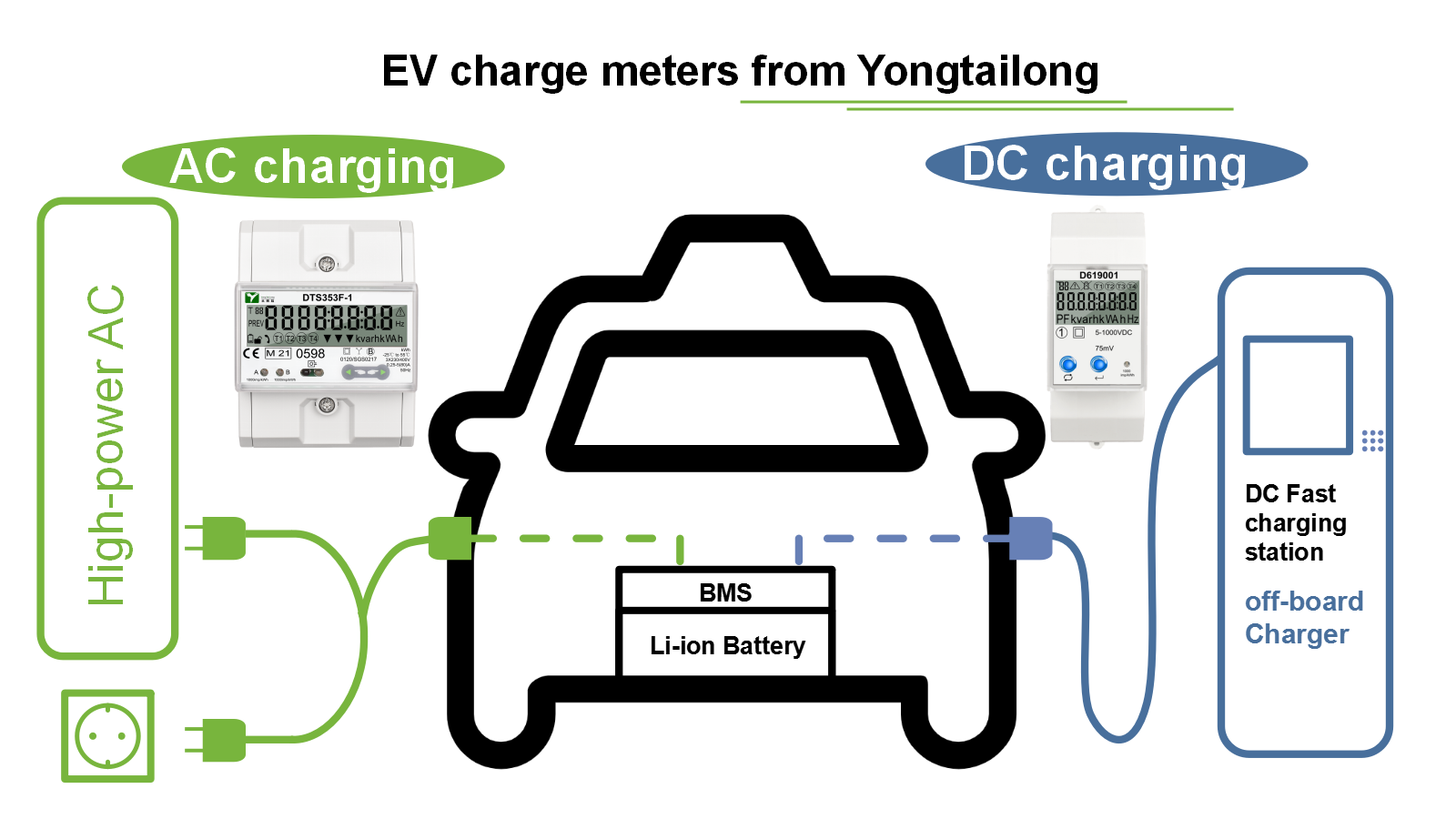

Although DC meters perform excellently in DC-side metering, in AC charging piles or AC-DC hybrid charging stations, Current Transformer (CT) meters are still needed to measure AC-side currents. In this case, DC meters and CT meters form a "DC-AC" metering closed loop:

- CT meters are responsible for measuring AC input currents (e.g., 380V three-phase electricity) and converting large currents into small currents (e.g., 5A) in proportion for AC energy meters to meter.

- DC meters are responsible for measuring DC output currents (e.g., 750V DC) and directly metering charging electricity consumption.

- System-level calibration: By comparing the energy conversion efficiency between the AC side and DC side (considering charging module losses), the accuracy of metering is further verified.

IV. Four Key Indicators for Selecting DC Meters: How to Avoid "Low-Quality Traps"?

Indicator 1: Accuracy Class and Range Matching

Choose DC meters that meet Class 0.5 or Class 0.2 (for DC) standards to ensure metering accuracy complies with national regulations. Meanwhile, the range should cover 1.2-1.5 times the maximum output current of the charging pile (e.g., for a 120kW charging pile with a maximum current of 300A, a DC meter with a 400A range should be selected).

Indicator 2: Harmonic Compensation Capability

If the charging pile serves a large number of harmonic sources (e.g., old EVs), select DC meters that support at least 5th harmonic compensation, and prioritize models certified to the IEC 61000-4-7 standard.

Indicator 3: Communication Protocols and Platform Compatibility

Based on the interface requirements of charging operation platforms (e.g., TELD, Star Charge), select DC meters that support protocols such as Modbus-TCP, IEC 61850, and OCPP 2.0 to ensure real-time data upload and remote calibration.

Indicator 4: Environmental Adaptability and Reliability

DC meters installed outdoors should have an IP65 protection rating (dustproof and waterproof), a working temperature range of -40℃ to +70℃, and pass EMC (Electromagnetic Compatibility) testing to avoid metering abnormalities caused by lightning strikes or power grid fluctuations.

Conclusion: Accurate Billing Starts with a DC Meter

As EV charging piles shift from "scale expansion" to "quality operation", DC meters are no longer just simple "metering tools", but rather "key links" connecting user trust, operator revenue, and power grid stability. Through high-precision current measurement, harmonic compensation, and bidirectional metering technologies, DC meters are ending the era of "estimated values" in billing, making the flow of every kilowatt-hour of electricity transparent, traceable, and fairly verifiable.

Choosing a DC meter means choosing a more transparent, efficient, and sustainable charging ecosystem. When every DC meter can become an "accurate scale" for billing, the popularization of EVs will have less controversy and more trust.

# Say Goodbye to "Estimated Values"! Practical Application of DC Meters for Accurate Billing in EV Charging Piles As electric vehicles (EVs) shift from being "policy-driven" to "market-driven", the billing accuracy of charging piles has become one of the core factors for users when choosing a service provider. However, traditional charging piles often suffer from disputes such as users being "overcharged" or operators experiencing "reduced revenue" due to issues like large current measurement errors and severe harmonic interference. As the "metering core" of charging piles, DC meters (DC energy meters), with their high accuracy, anti-interference capabilities, and bidirectional metering features, are reshaping the industry rules for charging billing. This article will use practical cases and technical analysis to reveal how DC meters fundamentally solve billing errors and inject "precision genes" into the EV ecosystem. ## I. The "Three Major Pain Points" of Traditional Charging Pile Billing: Where Do Errors Come From? ### Pain Point 1: "Ambiguous" Current Measurement, Billing Relies on "Estimated Values" Traditional charging piles mostly adopt a combined solution of shunts and ordinary energy meters: shunts convert large currents into small voltage signals, and energy meters calculate electricity consumption through integration. However, shunts have a temperature drift issue (for every 10℃ increase in temperature, the resistance value changes by 0.4%), leading to an expansion of current measurement errors as charging time increases. Additionally, ordinary energy meters have insufficient ability to capture dynamic currents (such as transient impacts during charging start/stop), and can only estimate electricity consumption based on "average values", resulting in an error rate often exceeding ±3%. ### Pain Point 2: "Amplified" Harmonic Interference, "False Increase" in Electricity Consumption Becomes Commonplace EV charging modules generate a large number of harmonics (especially 3rd and 5th harmonics). If traditional energy meters are not equipped with harmonic compensation functions, they will mistakenly count harmonic power as active power, leading to a "false increase" in electricity consumption. ### Pain Point 3: "Missing" Bidirectional Metering, V2G Services Struggle to Launch With the promotion of Vehicle-to-Grid (V2G) technology, charging piles need to support bidirectional metering for "charging-discharging". However, most traditional energy meters are designed for unidirectional use and cannot distinguish current direction, making it impossible to accurately calculate users' discharge revenue—a major obstacle to the commercialization of V2G. ## II. How Do DC Meters Solve Billing Problems? Revealing Three Core Technologies ### Technology 1: High-Precision Current Measurement: From "Estimation" to "Actual Measurement" DC meters use closed-loop Hall sensors or fluxgate sensors instead of shunts to achieve non-contact current measurement, completely eliminating the temperature drift issue. ### Technology 2: Harmonic Compensation and Effective Value Metering: Rejecting "False Increases" in Electricity Consumption DC meters have a built-in harmonic analysis module that can real-time separate fundamental wave power from harmonic power, and only integrate and meter the fundamental active power. ### Technology 3: Bidirectional Metering and Dynamic Tariffs: Supporting V2G and Time-of-Use Electricity Prices DC meters use bidirectional current sensors and dual-channel metering chips to simultaneously record charging and discharging electricity consumption. They also support dynamic tariff models such as time-of-use pricing and demand response. Moreover, DC meters can accurately calculate the revenue difference between charging and discharging, providing data support for V2G services. ## III. The "Golden Partnership" of DC Meters and CT Meters: Building a "Precision Metering Chain" for Charging Piles Although DC meters perform excellently in DC-side metering, in AC charging piles or AC-DC hybrid charging stations, Current Transformer (CT) meters are still needed to measure AC-side currents. In this case, DC meters and CT meters form a "DC-AC" metering closed loop: - CT meters are responsible for measuring AC input currents (e.g., 380V three-phase electricity) and converting large currents into small currents (e.g., 5A) in proportion for AC energy meters to meter. - DC meters are responsible for measuring DC output currents (e.g., 750V DC) and directly metering charging electricity consumption. - System-level calibration: By comparing the energy conversion efficiency between the AC side and DC side (considering charging module losses), the accuracy of metering is further verified. ## IV. Four Key Indicators for Selecting DC Meters: How to Avoid "Low-Quality Traps"? ### Indicator 1: Accuracy Class and Range Matching Choose DC meters that meet Class 0.5 or Class 0.2 (for DC) standards to ensure metering accuracy complies with national regulations. Meanwhile, the range should cover 1.2-1.5 times the maximum output current of the charging pile (e.g., for a 120kW charging pile with a maximum current of 300A, a DC meter with a 400A range should be selected). ### Indicator 2: Harmonic Compensation Capability If the charging pile serves a large number of harmonic sources (e.g., old EVs), select DC meters that support at least 5th harmonic compensation, and prioritize models certified to the IEC 61000-4-7 standard. ### Indicator 3: Communication Protocols and Platform Compatibility Based on the interface requirements of charging operation platforms (e.g., TELD, Star Charge), select DC meters that support protocols such as Modbus-TCP, IEC 61850, and OCPP 2.0 to ensure real-time data upload and remote calibration. ### Indicator 4: Environmental Adaptability and Reliability DC meters installed outdoors should have an IP65 protection rating (dustproof and waterproof), a working temperature range of -40℃ to +70℃, and pass EMC (Electromagnetic Compatibility) testing to avoid metering abnormalities caused by lightning strikes or power grid fluctuations. ## Conclusion: Accurate Billing Starts with a DC Meter As EV charging piles shift from "scale expansion" to "quality operation", DC meters are no longer just simple "metering tools", but rather "key links" connecting user trust, operator revenue, and power grid stability. Through high-precision current measurement, harmonic compensation, and bidirectional metering technologies, DC meters are ending the era of "estimated values" in billing, making the flow of every kilowatt-hour of electricity transparent, traceable, and fairly verifiable. Choosing a DC meter means choosing a more transparent, efficient, and sustainable charging ecosystem. When every DC meter can become an "accurate scale" for billing, the popularization of EVs will have less controversy and more trust.

English

English 简体中文

简体中文

.png?imageView2/2/w/500/h/500/format/png/q/100)

.jpg?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)