With the rapid increase in the global number of new energy vehicles and the acceleration of energy transformation, the technological demands for electric vehicle charging pile meters are undergoing profound changes. Combining policy guidance, market demands, and technological innovation, the future of electric vehicle charging pile meters will present the following six major trends:

1. High-precision measurement and intelligent management: Electric vehicle charging pile meters evolve from "simple billing" to "energy hubs"

The measurement accuracy in the ultra-fast charging era soars

Technical drive: The popularization of 800V high-voltage platforms and liquid-cooled supercharging piles with power over 480kW requires electric vehicle charging pile meters to support precise measurement of 600A DC current, with energy register resolution enhanced to the 0.01 kWh level to cope with scenarios such as "5 minutes of charging, 300 kilometers of driving range".

Function expansion: Electric vehicle charging pile meters integrate edge computing chips to achieve real-time power distribution, multi-rate metering (such as dynamic switching of peak and off-peak electricity prices), and V2G bidirectional metering, providing data support for intelligent dispatching algorithms.

Intelligent scenario coverage

Automatic rate switching: By learning users' charging habits through AI, charging is automatically initiated during off-peak hours. For pure electric vehicle users who choose time-of-use electricity prices, annual electricity bills can be reduced by 31%.

Fault prediction: Based on historical data, predict the aging or measurement deviation of electric vehicle charging pile meters and take early intervention to avoid economic losses.

II. Energy Interconnection and System Integration: Building a Closed Loop of "Power Generation - Energy Storage - Power Consumption"

Integrated Light, Storage and Charging

Technology Integration: The electricity meter of the charging pile needs to be compatible with the energy flow monitoring of photovoltaic power generation, energy storage systems and charging piles. The light, storage and charging station increases the proportion of clean energy to 60% and reduces carbon emissions by 30% - 50% through an intelligent EMS system.

Off-grid operation capability: Supports microgrid mode, maintains charging services through energy storage batteries when the power grid fails, and realizes off-grid operation with the support of V2G technology.

Popularization of DC bus architecture

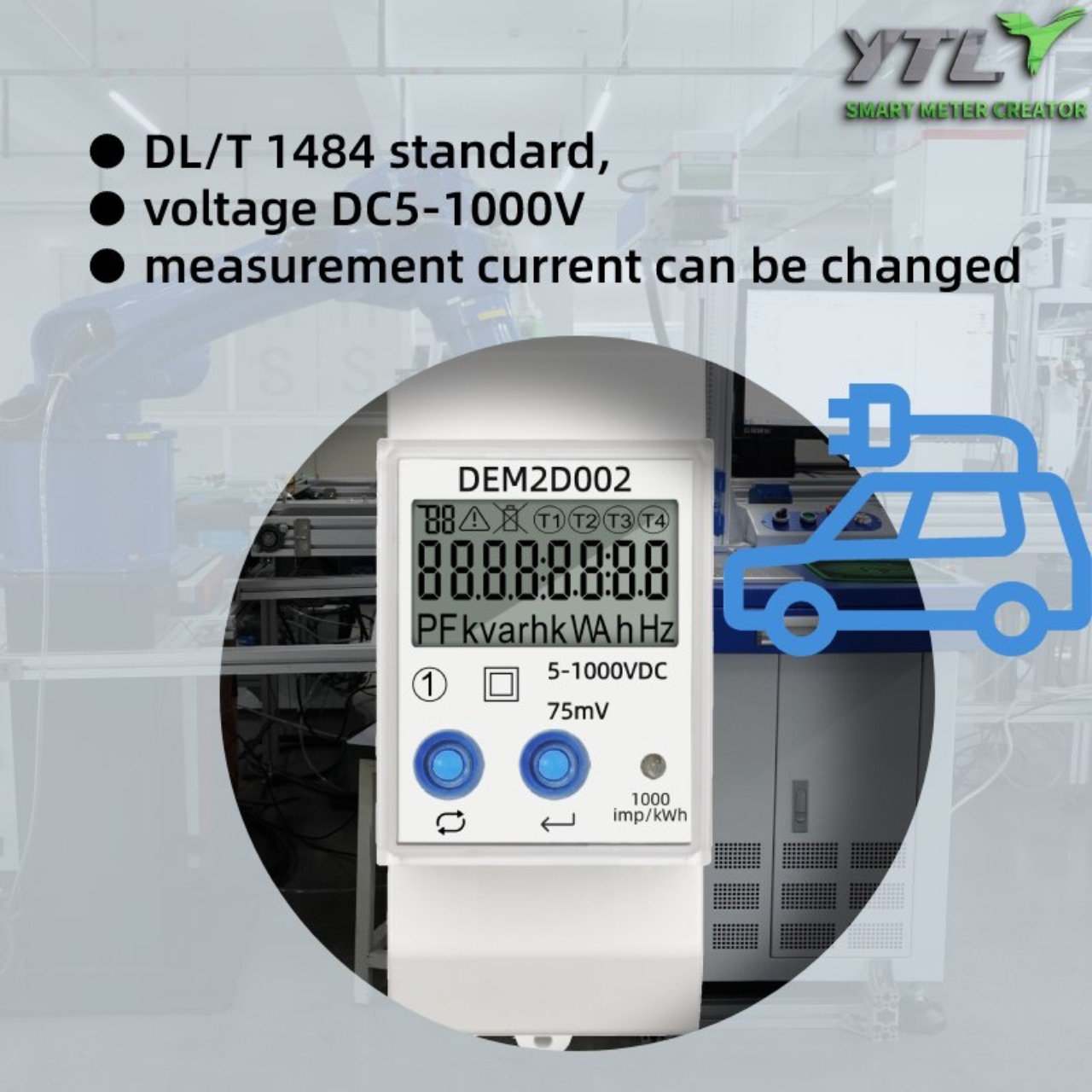

Efficiency improvement: By 2025, the proportion of DC bus in the light, storage and charging system will reach 75%, and the loss of AC/DC conversion will be reduced by 5% - 8%. The electricity meter of the charging pile needs to be compatible with the high-voltage DC environment and support 1000V voltage input.

III. Dual Drive of Policy and Market: Accelerating Function Iteration

Time-of-use electricity price response mechanism

Policy adaptation: Optimize the peak and off-peak period division of charging piles, and the electricity meter of the charging pile needs to support dynamic rate switching to guide users to charge during off-peak hours.

Demand-side response: Integrate V2G function, and encourage users to supply power in reverse through price signals. The electricity meter of the charging pile needs to support bidirectional metering function.

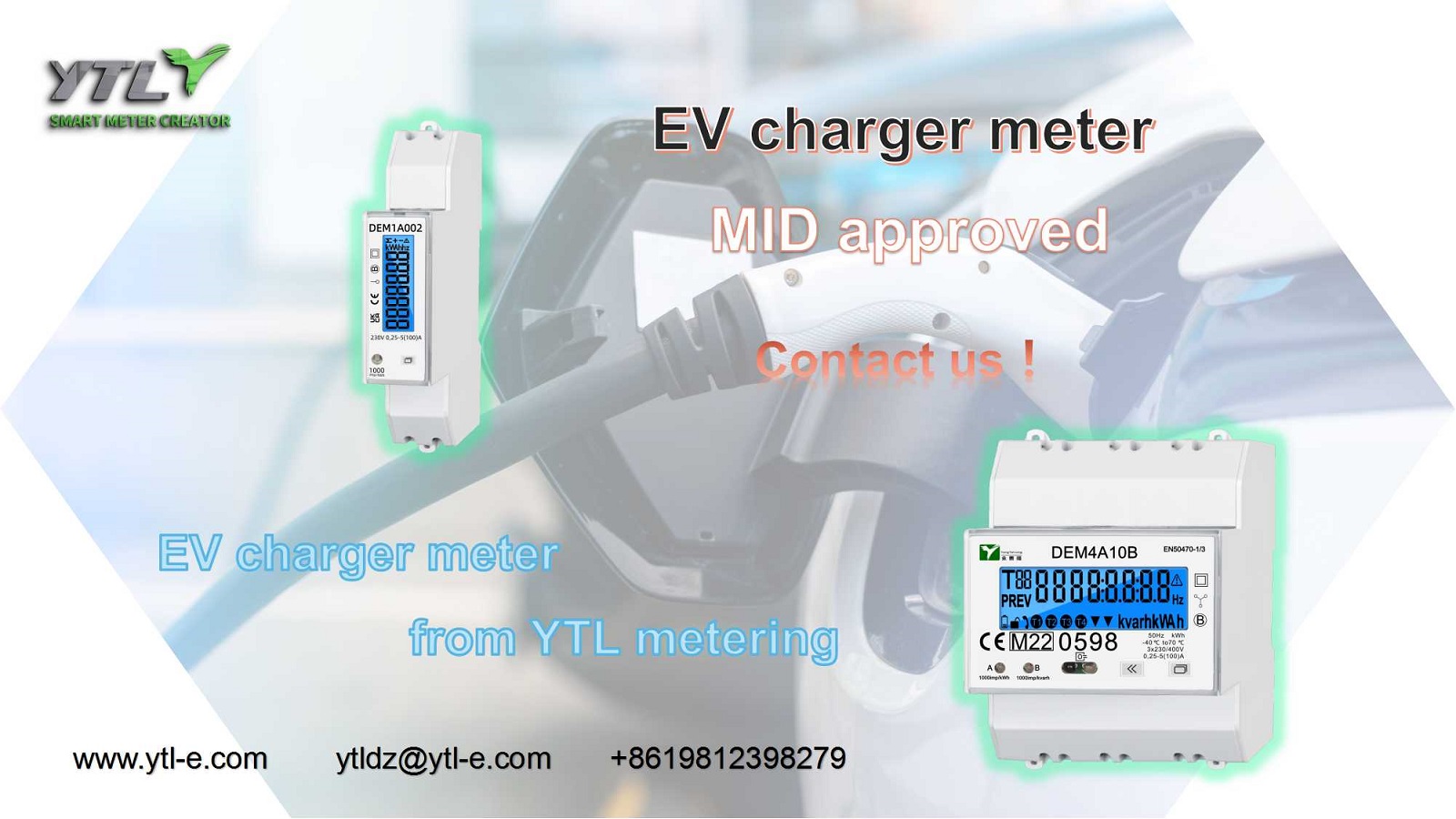

International certification: Adapt to overseas standards such as CCS and CHAdeMO. For example, Huawei's super charging piles have passed the EU CE certification, and the export proportion has increased to 22%. The electricity meter of the charging pile needs to meet the certification requirements of the country or region, such as European MID certification, North American UL certification, and Chinese CPA certification.

IV. Reliability and Safety: Stable Operation in Extreme Environments

Enhanced Environmental Adaptability

Wide Temperature Range Design: The charging piles adopt liquid cooling technology, supporting operation in environments ranging from -30°C to 60°C. The liquid metal battery maintains a capacity retention rate of over 85% at low temperatures. The electricity meters of the charging piles also need to meet the requirements of environments and are designed for a temperature range of -40°C to 70°C.

Improved Protection Grade: IP65 dustproof and waterproof becomes the standard, suitable for heavy-duty scenarios such as ports and mines.

Upgraded Safety Certification

Electromagnetic Compatibility: Passed IEC 61000-4 series tests, capable of withstanding lightning strikes and harmonic interference.

Data Encryption: Supports the national cipher SM4 algorithm to prevent tampering of metering data.

V. Cost Optimization and Business Model Innovation: From "Equipment Sales" to "Service Operations"

Breakthroughs in Cost Reduction

Material Innovation: The penetration rate of silicon carbide power devices exceeds 60%, increasing the power density of the charging module by three times and achieving a conversion efficiency of over 98%.

Scale Effect: The cost of lithium iron phosphate batteries has dropped to 0.25 yuan/Wh, reducing the full life cycle cost by 34%.

Data Monetization: The charging behavior data collected by the electricity meters of the charging piles can be used by insurance companies for risk assessment or by power grids for load forecasting.

English

English 简体中文

简体中文

.png?imageView2/2/w/500/h/500/format/png/q/100)

.png?imageView2/2/w/500/h/500/format/png/q/100)