As a key equipment in the field of industrial measurement, high-precision digital displays are continuously expanding their application scope with technological progress and industrial upgrading. This instrument, which can accurately display various electrical and non electrical parameters in digital form, plays an irreplaceable role in many industries due to its excellent measurement performance, stable working characteristics, and convenient reading methods. From traditional industrial control to emerging intelligent manufacturing, from energy management to scientific experiments, high-precision digital displays meet the strict requirements for measurement accuracy and reliability in different application scenarios with their excellent performance, demonstrating broad market prospects.

In the field of industrial automation and process control

In the field of industrial automation, high-precision digital displays are indispensable measurement and display devices. These instruments are widely used in various automation control systems and production equipment to monitor and display key parameters such as voltage, current, power, frequency, temperature, pressure, and flow in real-time. In the intelligent manufacturing workshop, digital displays provide operators with intuitive data on the operating status of equipment, helping to achieve precise control of the production process. In the mechanical processing industry, digital displays are used in conjunction with sensors to accurately display mechanical parameters such as position, displacement, and speed, ensuring processing accuracy. In the process industry, digital displays are used to monitor process parameters such as pipeline flow rate, container pressure, and medium temperature to ensure safe and stable production operation. With the advancement of Industry 4.0 and intelligent manufacturing, high-precision digital displays are deeply integrated with technologies such as the Internet of Things and cloud computing, developing towards intelligence and networking to meet the higher requirements of modern industry for data collection and monitoring.

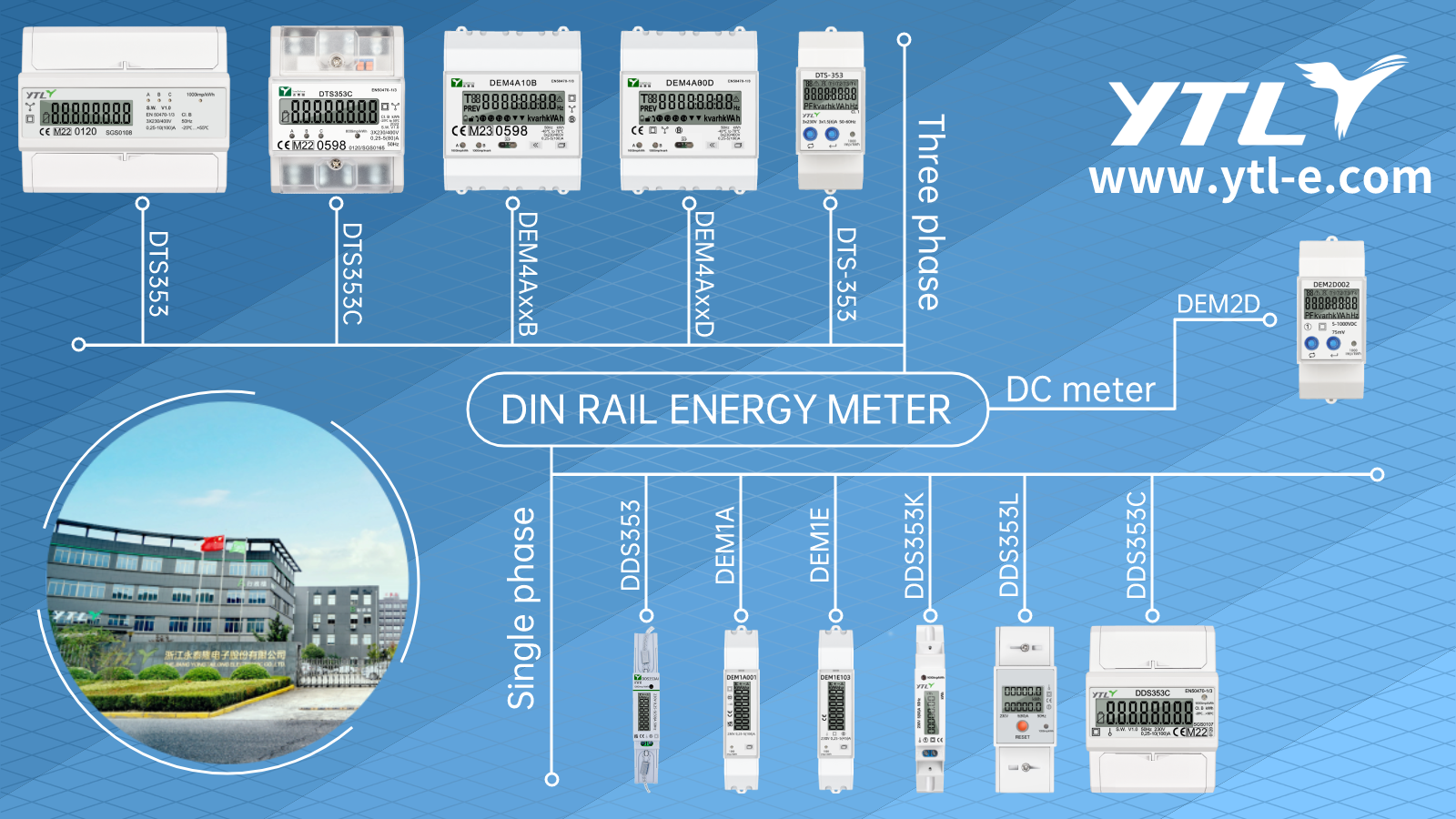

Energy Management and Power Monitoring System

The field of energy management is an important application market for high-precision digital displays. In the construction of smart grids, digital displays serve as the basic measurement units and are installed in various levels of distribution systems to achieve accurate measurement and real-time display of electrical energy parameters. In energy management of industrial and commercial buildings, digital displays are used for sub item measurement and energy consumption monitoring, providing data support for energy conservation and consumption reduction in enterprises. In the field of new energy, digital displays are used for monitoring systems such as photovoltaic power generation and wind power generation, accurately measuring power generation and system efficiency. In addition, digital displays are widely used in important power places such as substations, distribution rooms, and data centers to achieve continuous monitoring of power supply quality and equipment operation status. With the development of energy Internet, high-precision digital display is deeply integrated with the energy management system to support the collection, analysis and optimization of energy data and provide technical support for improving energy utilization efficiency.

Scientific experiments and testing measurement industry

In the fields of scientific research and high-precision testing, high-precision digital displays occupy an important position due to their excellent measurement performance. Various laboratories and research institutions use digital displays as standard measuring instruments for precise measurement of physical quantities, chemical quantities, and biomass. In the field of metrological verification, digital displays are used as standard instruments for the calibration and verification of various instruments and meters. In the process of product development and quality control, digital displays provide reliable testing data to ensure product quality. In professional fields such as environmental monitoring, material analysis, and medical diagnosis, digital displays are combined with specialized sensors to achieve accurate measurement of various professional parameters. With the advancement of technology, high-precision digital displays are developing towards higher precision, more functions, and stronger compatibility, meeting the increasing requirements of scientific research for measurement accuracy.

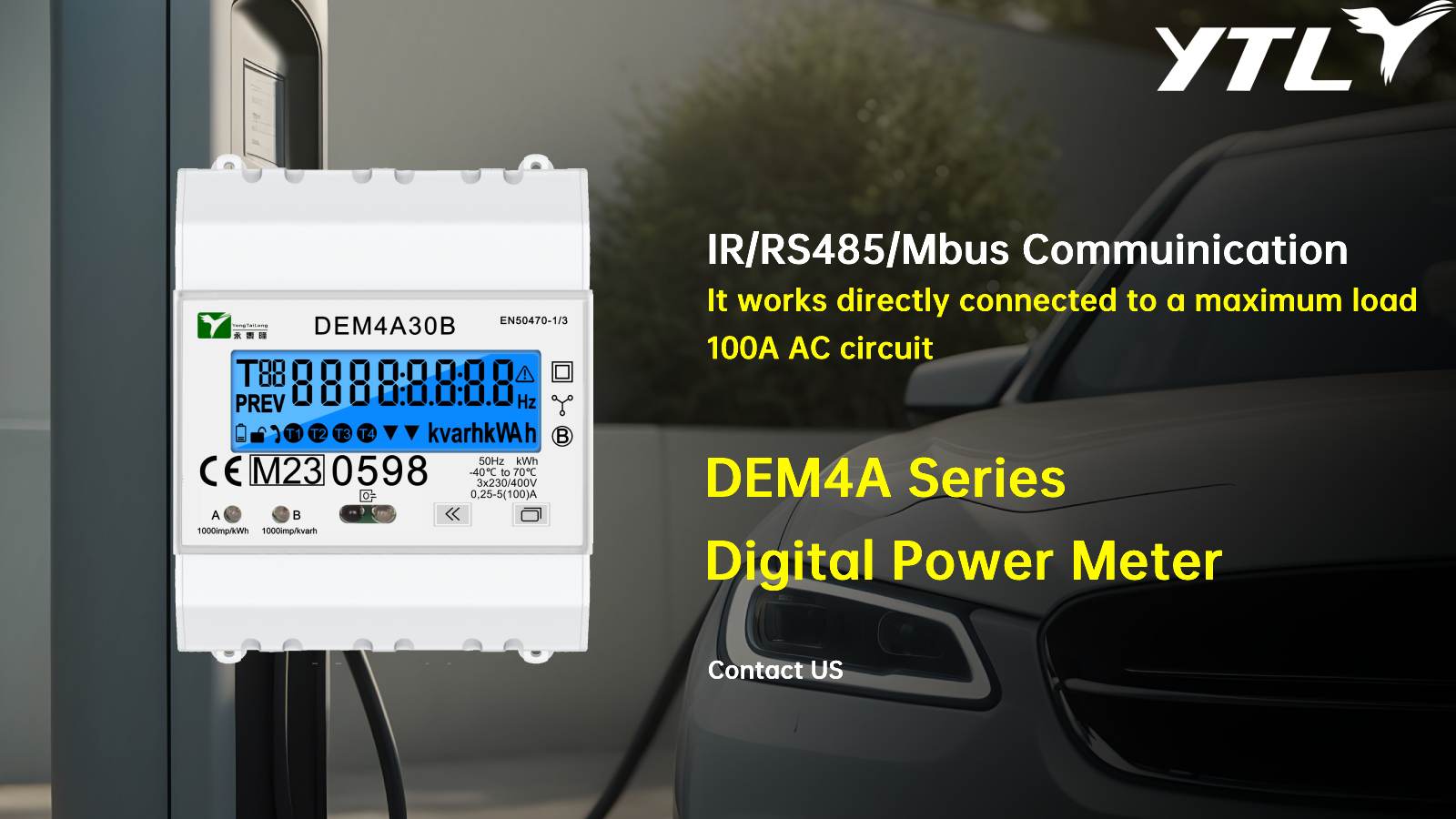

Transportation and infrastructure construction

The demand for high-precision digital displays in the transportation industry continues to grow. In the rail transit system, digital displays are used to monitor the operating parameters of traction power supply, signal systems, and vehicle equipment. In large transportation hubs such as airports and ports, digital displays enable real-time monitoring of power supply systems and important equipment. In electric vehicle charging facilities, digital displays accurately display charging parameters to ensure charging safety. In the construction of smart cities, digital displays are applied in fields such as municipal facility monitoring and environmental monitoring. With the advancement of new infrastructure, the application of high-precision digital displays in new infrastructure such as 5G base stations, data centers, and artificial intelligence is becoming increasingly widespread, providing support for the development of smart cities and digital economy.

Future Market Development Trends and Prospects

The market prospects for high-precision digital displays are broad, showing a clear development trend. In terms of technological innovation, digital displays are developing towards higher precision, faster response, and stronger functionality, with integrated and modular design becoming mainstream. In terms of application areas, with the development of emerging industries, the application of digital displays in fields such as new energy, intelligent manufacturing, and the Internet of Things will continue to deepen. In terms of market demand, the demand for intelligent and networked digital display products is rapidly increasing, and intelligent digital display meters that support remote monitoring and data analysis will become the mainstream in the market. In terms of industrial ecology, digital display manufacturers are transforming from single product suppliers to solution providers, providing customers with more comprehensive services. These development trends indicate that high-precision digital displays will play an important role in more fields, and the market space will further expand.

As an important representative of modern measurement technology, high-precision digital displays are continuously expanding their application market with technological development and industrial upgrading. From industrial control to energy management, from scientific experiments to transportation, digital displays provide important support for the development of various industries with their outstanding performance and reliability. With the deepening of digital transformation, the technological level and application value of high-precision digital displays will be further enhanced, making greater contributions to economic and social development.

English

English 简体中文

简体中文

.png?imageView2/2/w/500/h/500/format/png/q/100)

.jpg?imageView2/2/w/500/h/500/format/png/q/100)